1 - 21 of 21 results

Showing 1 - 21 of 21 Products

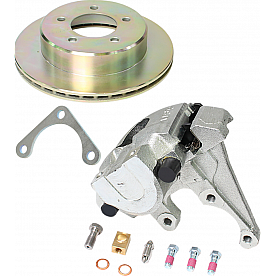

Trailer Disc Brakes are a type of braking system commonly used in various vehicles like cars, trucks, and trailers. They function by using calipers to squeeze pairs of pads against a disc to create friction, slowing down the rotation of the axle, and as a result, the vehicle. The disc in this system is usually made from cast iron, but in some high-performance vehicles, it might be made from composites such as reinforced carbon or carbon-ceramic matrix composites.

Disc brakes consist of a disc or "rotor," brake pads, a caliper, and the associated hydraulic system. The rotor is attached directly to the wheel. Brake fluid, under pressure from the master cylinder, is pushed into the caliper where it presses against the piston. The piston, in turn, squeezes the brake pads against the rotor. This friction between the pads and the rotor causes the vehicle to slow down and stop.

Advantages of Trailer Disc Brakes:

1. Faster response: Disc brakes respond faster than drum brakes, providing shorter stopping distances especially important in instances of emergency braking.

2. Less prone to overheating: The open design of disc brakes means they cool down more quickly than drum brakes, which are enclosed. This prevents overheating during prolonged use and provides more consistent braking performance.

3. Better performance in wet conditions: Disc brakes have superior water-shedding capabilities. If a vehicle goes through a water puddle, the water can quickly be expelled or removed from the brake disc due to its open design, thereby improving brake performance in wet conditions.

4. Less maintenance: Disc brakes generally require less maintenance than drum brakes. They don’t need to be adjusted as frequently, have fewer parts to worry about, and are easier to replace when needed.

5. Higher durability: Disc brakes are more durable and wear-resistant compared to other types of brakes, making them a more cost-effective option in the long run.

6. Better heat dissipation: As the braking surface is directly exposed to the air, disc brakes are better at dissipating heat. This makes them less likely to fail or fade under harsh or heavy braking conditions.

7. Easier inspection: It’s easier to visually inspect disc brakes for wear and tear, which can simplify and expedite routine maintenance checks.

Disc brakes consist of a disc or "rotor," brake pads, a caliper, and the associated hydraulic system. The rotor is attached directly to the wheel. Brake fluid, under pressure from the master cylinder, is pushed into the caliper where it presses against the piston. The piston, in turn, squeezes the brake pads against the rotor. This friction between the pads and the rotor causes the vehicle to slow down and stop.

Advantages of Trailer Disc Brakes:

1. Faster response: Disc brakes respond faster than drum brakes, providing shorter stopping distances especially important in instances of emergency braking.

2. Less prone to overheating: The open design of disc brakes means they cool down more quickly than drum brakes, which are enclosed. This prevents overheating during prolonged use and provides more consistent braking performance.

3. Better performance in wet conditions: Disc brakes have superior water-shedding capabilities. If a vehicle goes through a water puddle, the water can quickly be expelled or removed from the brake disc due to its open design, thereby improving brake performance in wet conditions.

4. Less maintenance: Disc brakes generally require less maintenance than drum brakes. They don’t need to be adjusted as frequently, have fewer parts to worry about, and are easier to replace when needed.

5. Higher durability: Disc brakes are more durable and wear-resistant compared to other types of brakes, making them a more cost-effective option in the long run.

6. Better heat dissipation: As the braking surface is directly exposed to the air, disc brakes are better at dissipating heat. This makes them less likely to fail or fade under harsh or heavy braking conditions.

7. Easier inspection: It’s easier to visually inspect disc brakes for wear and tear, which can simplify and expedite routine maintenance checks.