Purging of RV LP-Gas Containers

PURGING OF LP-GAS CONTAINERS,

DETERMINING TOTAL LOAD & VAPORIZATION RATES

A very important step which must not be overlooked by RV owners is the importance of properly purging new LP-Gas cylinders. Consider the following:

- Both ASME and DOT specifications require hydrostatic testing of containers and cylinders after This usually done with water.

- Before charging with propane, the container or cylinder will contain the normal amount of air. Neutralizing Moisture from Cylinders:

Both water and air seriously interfere with proper operation of the LP Gas system and connected appliances. If not removed, they will result in costly service calls and needless expense far exceeding the normal cost of proper purging.

Even if a careful inspection of the cylinder reveals no visible moisture, the cylinder must still be neutralized. Condensation may have formed on the interior walls and the air inside the cylinder may have relative humidity up to 100%.

The Importance of Purging Air:

The resulting issues will result if the natural volume of atmosphere in the cylinder is not removed.

- Spring and summer installations will experience false and excessive cylinder pressure. This will cause the safety relief valve to open, blowing off the excess pressure.

- The air mixture present in the vapor space will be carried to the appliances.

- If a vapor return equalizing hose is not used, the contained air will be compressed above the liquid level, resulting in cylinder filling slow.

If atmospheric air is properly purged from the cylinder the cylinder will fill faster, appliances will perform more consistently and relief valves will be less likely to pop off.

Never purge with liquid:

The wrong way is of course the easiest way. Never purge a cylinder with liquid propane. To do so causes the liquid to flash into vapor, chilling the cylinder, and condensing any moisture vapor on the walls where it remains while the pressure is being blown down. Also less than 50% or as little as 25% of the air will be removed by this easy but wrong method.

Purging Air:

The natural volume of air in all cylinders must be removed before the first fill. The correct method for purging air is as follows. Note that purging of air MUST be done at the LP-Gas dispenser for safety.

- Install a gauge adapter assembly on the service valve POU Type 1 outlet connection. Exhaust to atmosphere any air pressure in the

- Open the valve on the outlet end of the vapor equalizing hose, slowly to avoid slugging the excess flow valve on the dispenser. Carefully observe the pressure gauge.

- When the gauge reading shows 15 PSI, shut off the vapor valve on the hose.

- Open the exhaust line exhausting vapor out the exhaust stack to atmosphere

- Repeat steps 4 to 5 more times.

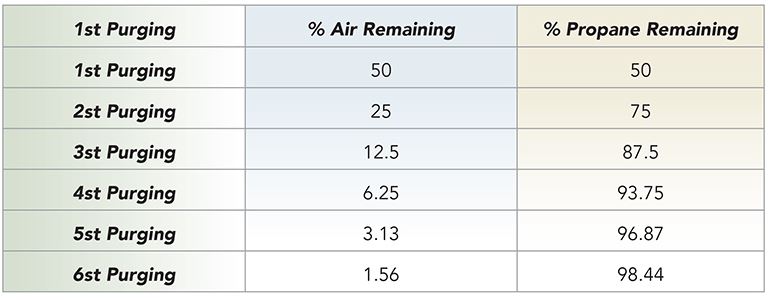

After the previous steps have been performed, the percent of air in the cylinder is reduced as shown in the following table.

For LP-Gas containers that are pre-purged it is not necessary to follow the purging steps above. Air and moisture have already been removed from pre-purged cylinders.

** The chart on this page is reprinted with permission of NFPA 58, LP-Gas Code, and National Fire Protection Association. This reprint is not the complete and official position of NFPA on the referenced subject which is represented only by the standard in its entirety.

Determining Total Load & Vaporization Rates

To properly size the cylinder, regulator, and piping for a unit, total load must be determined. Determining total load is the sum of all propane gas used and is expressed in BTU/Hr. (British Thermal Units per Hour).

The BTU information can be found on the nameplate of the appliance or in the manufacturer's literature. Remember to allow for appliances which may be added at a later dated. This will eliminate the need for later revisions.

Vaporization is the rate at which liquid propane boils off and becomes vapor. The larger the dampened surface of the container, the faster the liquid boils off into vapor. Therefore, the vaporization rate of a container is dependent upon the temperature of the liquid and the amount of dampened surface of the container.

In determining the proper size container to handle a unites total load, the lowest winter temperature must be taken into account.

It is important to know that because of various sizes of the containers, the dampened surface area will be different and therefore, the vaporization rates will be different.

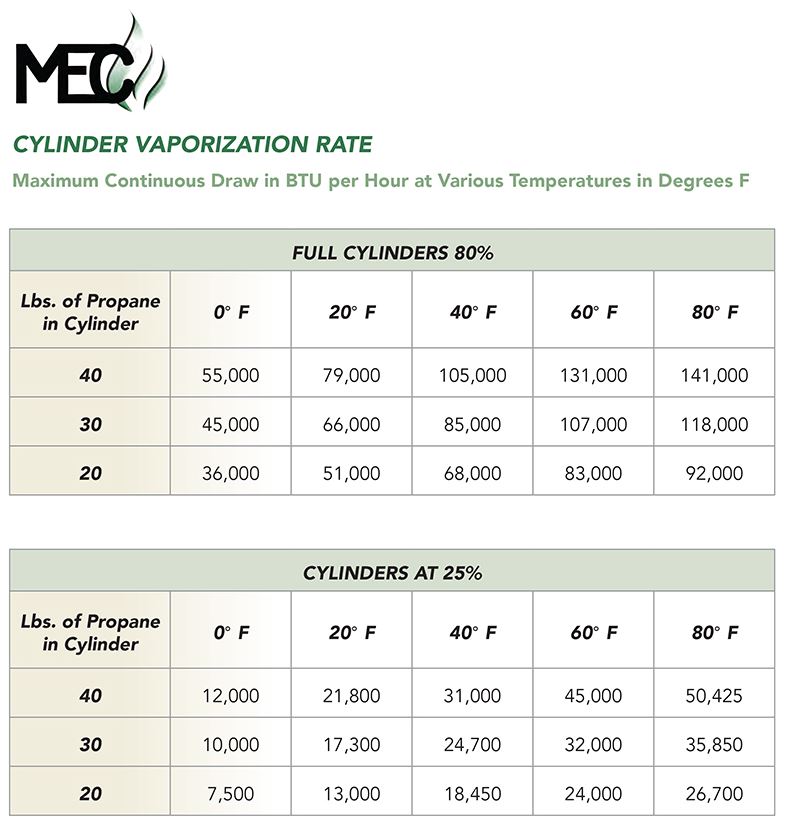

The table below shows the vaporization rate of cylinders in terms of temperature of the liquid and the wet surface area of the cylinder. When the temperature is lower or if the container has less liquid in it, the vaporization rate of the cylinder is a lower value.

The table below serves as a reference in estimating what a certain cylinder size will provide under different temperatures. The table references cylinders that are full/80% and at 25%.